How Bamboo BBQ Skewers Are Made: From Forest to Table

- Share

- publisher

- Sunny

- Issue Time

- Sep 5,2025

Summary

Discover how eco-friendly bamboo BBO skewers are made-from raw bamboo harvesting tocutting, polishing, pointing, and automatic packing.

From Bamboo to Skewer: Exploring the Production Journey

When it comes to enjoying a great barbecue, there's one essential tool we can't do without-bamboo skewer. Many people search online for "BBQ skewers", and while some just want to buy them, others are curious about how they're made by the factory. Today, let's take a tour inside our bamboo skewer factory and explore the complete production process.

Sustainable Material Selection

Our production starts with carefully chosen raw bamboo. Near Wuyi Mountain in Fujian, we have our own 666 hectares of bamboo forest. This natural environment provides the bamboo with rich nutrients, making it strong, flexible, and ideal for skewer production. Once harvested, the bamboo is transported to the mill and cut into workable sections

Cutting and splitting

Inside the workshop, we use advanced equipment, including a six-head automatic bamboo saw and three high-efficiency splitters. These machines cut the bamboo poles into sections and split them into thin strips, preparing them for the next stage of processing.

Drawing and Drying

The bamboo strips are then shaped into uniform filaments with a strip-forming machine. To ensure strength and durability, the strands are stacked crosswise and naturally dried under controlled temperature and humidity. This drying process is crucial to prevent cracking, mildew, and ensure that the skewers are long-lasting.

Polishing

Once dried, the bamboo filaments are chopped into the required lengths according to customer specifications. They are then polished in a dedicated polishing machine, which removes splinters and creates a smooth, user-friendly surface.

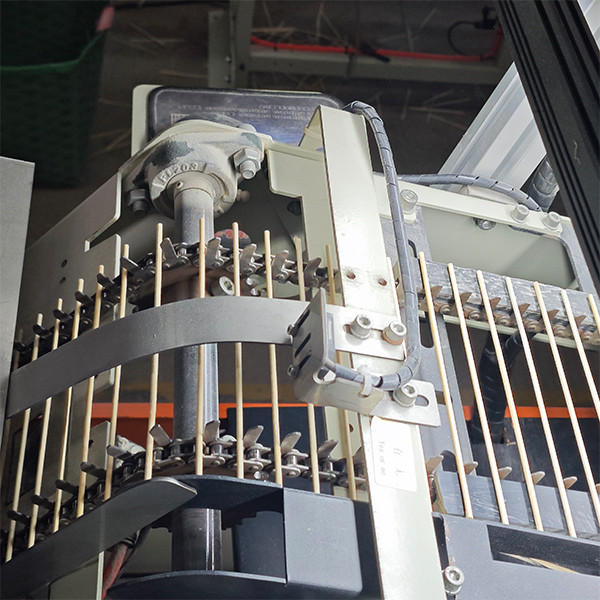

Screening and Pointing

Next comes quality refinement. The sticks are carefully screened to remove any imperfect pieces. Using 30 automated pointing machines, we shape the tips according to purpose:

Round tips- perfect for candied fruits, cotton candy, or children's snacks.

Sharp tips-ideal for grilling meat, seafood, and vegetables.

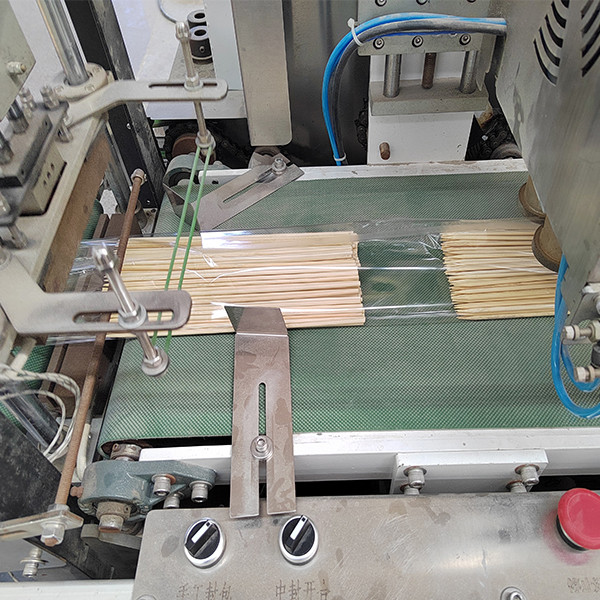

Automatic Packing

Once pointed, the skewers move to our automatic packaging line. They are typically packed in bags of 80 or 100 pieces. We also provide fully customizable pack sizes. Finally, the bags are boxed into cartons and prepared for shipment worldwide.

Advantages of YADA Bamboo Skewers

As a leading manufacturer of bamboo skewer sticks, YADA offers high-quality skewer bamboo sticks for both food service and household use. Our disposable bamboo sticks are durable, smooth, and splinter-free, ensuring safety and convenience in every use. From barbecue to catering events, each bamboo stick skewer is crafted under strict quality control, making them reliable for both hot and cold food applications.

One of the key advantages of YADA is the ability to provide custom packaging solutions. Whether you need bulk packs for wholesalers, retail-ready packaging, or personalized branding, we adapt to your specific business needs. This flexibility highlights your brand identity and ensures your customers receive eco-friendly, hygienic bamboo skewer sticks in a professional presentation.

Choose YADA, Choose Stability

Selecting YADA bamboo skewers means securing a reliable supply chain and a trusted supplier. With our 42,000m Fujian factory, dozens of production lines, abundant raw materials, and a monthly export capacity of over 1,500 tons, YADA guarantees consistency, quality, and on-time delivery for your business.

MOQ: 1 Carton. Smooth, no splinter, sturdy and great length for grilling, Eco-Conscious Grilling Made Easy and Hassle-Free.

Wholesale MOQ: 1 Carton. No Splinter, Sturdy Safe and Simple Grilling Solution. Automatic Drying and Polishing Production Line

YADA 250mm Eco Flat Bamboo Skewers for Meat Wholesale | Disposable Bamboo Skewer |Chicken Sticks BBQ

100% natural. Does not absorb odors. Heat and stain resistant. Excellent finish. High-Temperature Tolerance.Best Meat Grilling

YADA 120mm Teppo Gushi-gun Shaped Bamboo Skewer Wholesale|Disposable Customized Bamboo Skewers Stick

100% natural, Smooth, no splinter, sturdy and great length for grilling